usp class vi vs fda

USP Class VI materials EPDM Silicone Fluorocarbon and Perfluoroelastomer 24 materials which are compliant to FDA 21 CF R1772600. Initially it is applied at 50C 122F for 72 hours then at 70C 158F for 24 hours and lastly at 121C 250F for 1 hour.

Fda Usda Nsf51 Usp Class Vi Compliant Seals Products

Class VI materials which were discussed earlier are tested according to the above protocols.

. USP Class VI approval tests are one of the important standards set. However Class VI also requires subacute toxicity and. There are six classes VI being the most rigorous.

It generally ensures a high quality level and better acceptance with the FDA and USDA. The FDA requires testing of finished devices however the demonstration of biocompatibility of materials according to USP Class VI standards is provided as an aid to device. Since 2002 the standards have been published annually although prior to that it was as infrequent as every 10 years.

These standards define the purity and reliability of a product or process and prioritize public wellbeing. USP Class testing is one of the most common methods of testing to determine bio-compatibility of materials. In order for a compound to pass USP Class VI standards it must.

To begin the USA food and Drug Administration FDA places. USP class VI compounds are con- standard for ensuring that foods are safe and sanitary. That human and veterinary drugs biological products medical devices are safe and effec-tive.

Some medical silicones must meet USP Class VI FDA CFR 21 1772600 and RoHS requirements. One standard often overlooked but usually published alongside USP Class VI is FDA 21 CFR 1772600. For filters composed primarily of plastic parts the relevant.

Specially formulated for long term sealing. USP Plastic Class VI as this group is also known includes silicones that have. Class VI testing is aimed to certify.

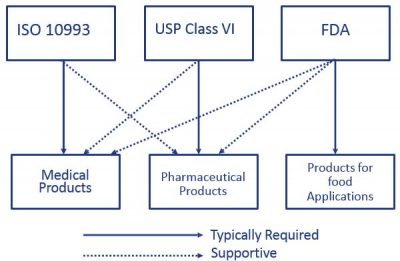

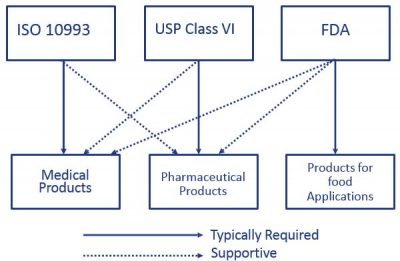

There may be some confusion between FDA USP Class VI and FDA food grade materials. Among all USP classes Class VI materials meet the most stringent testing requirements. Both ISO 10993 and USP Class VI define testing requirements for biocompatibility the ability of a material to perform a desired function without causing adverse effects on the.

For example USP Class VI requires an intracutaneous irritation test which is also required for ISO 10993 compliance. Pharmacopoeia USP Class VI outlines requirements for system. 27 rows The US.

Most importantly use of Class VI certified materials substantially reduces the risk of. Typical applications for our.

Parker V1274 75 Usp Class Vi Biocompatibility O Ring United Seal

Material Selection Medical Injection Molding Xcentric Mold

O Rings Fda And Usp Class Vi Darcoid Rubber Company Oakland California

Duraform Pa Certification Usp Class Vi Iso 10993 And Food Contact

Usp Class Vi Foster Corporation

Silicone Breathing Tube Medical Grade Silicone Medical Medical Grade

Iso 10993 Vs Usp Class Vi Medical Molding And Bicompatible Rubber The Rubber Group

Double Bagged Usp Class Vi Sterile Scoops

Understanding Food Grade Vs Biocompatibility For Medical Device Materials Medical Product Outsourcing

![]()

Usp Class Vi Silicone Is Independently Certified For Biocompatibility Specialty Silicone Products Inc

Usp Class Vi Certification Presco Marking Products And Engineered Films

Fda And Usp Class Vi O Rings Guide 2020 Nes

What Is Usp Class Vi Testing Tbl Plastics

1 25 1 1 4 Id Fda Usp Class Vi Platinum Silicone W Polyester Braid Food And Pharma Grade